Contents

- 1 8D Training Material

- 2 Introduction To 8D Disciplines

- 3 8D Training Material For Free

- 4 Objectives of Web-based 8D Training

- 5 Problem Solving Inhibitors

- 6 Types of Problem Solving

- 7 What Is Meant By 8D?

- 8 Where Does It Come From?

- 9 8D/8 Steps of Problem Solving Methodology?

- 10 Applying 8D Methodology?

- 11 8D vs Continuous Improvement?

- 12 Advantages of 8D Methodology

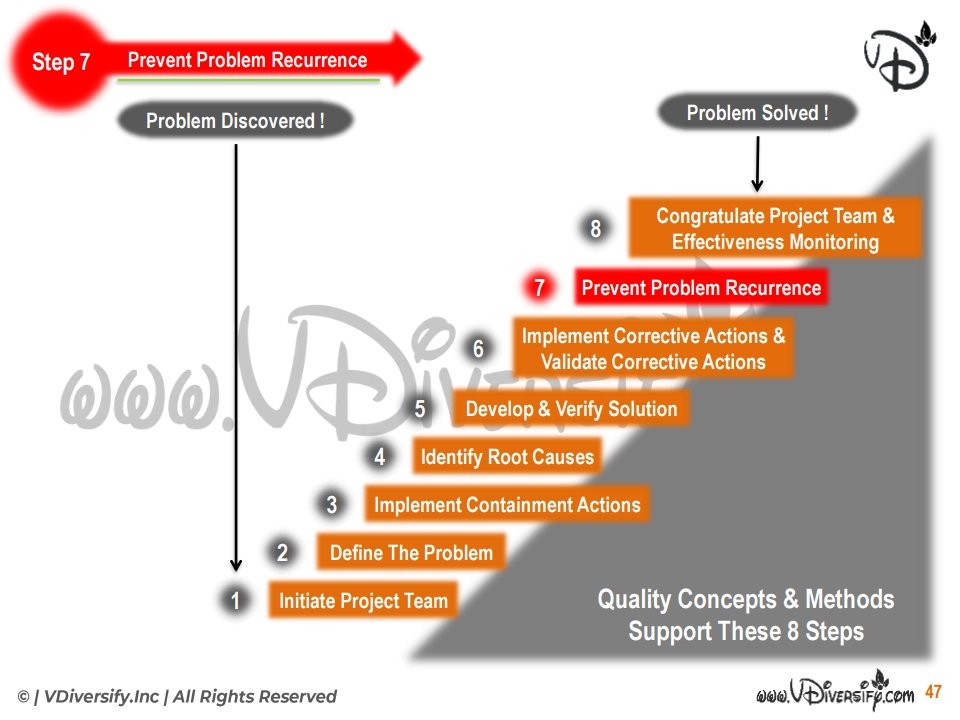

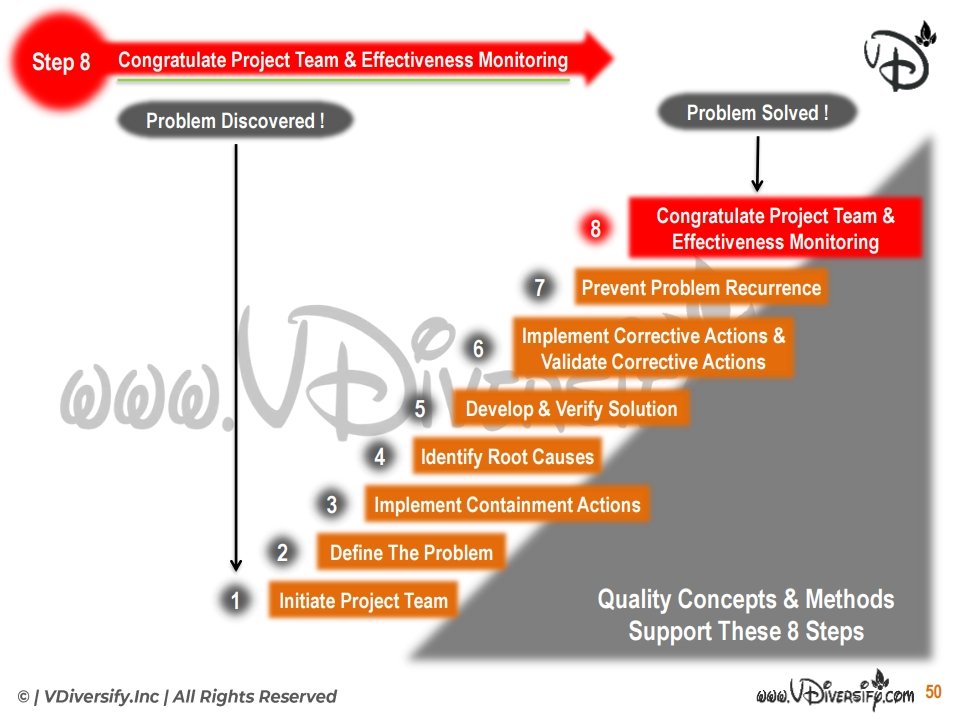

- 13 8D Disciplines | 8D Steps [2022]

- 13.1 Step 1: Initiate The Project Team

- 13.2 Step 2: Define The Problem

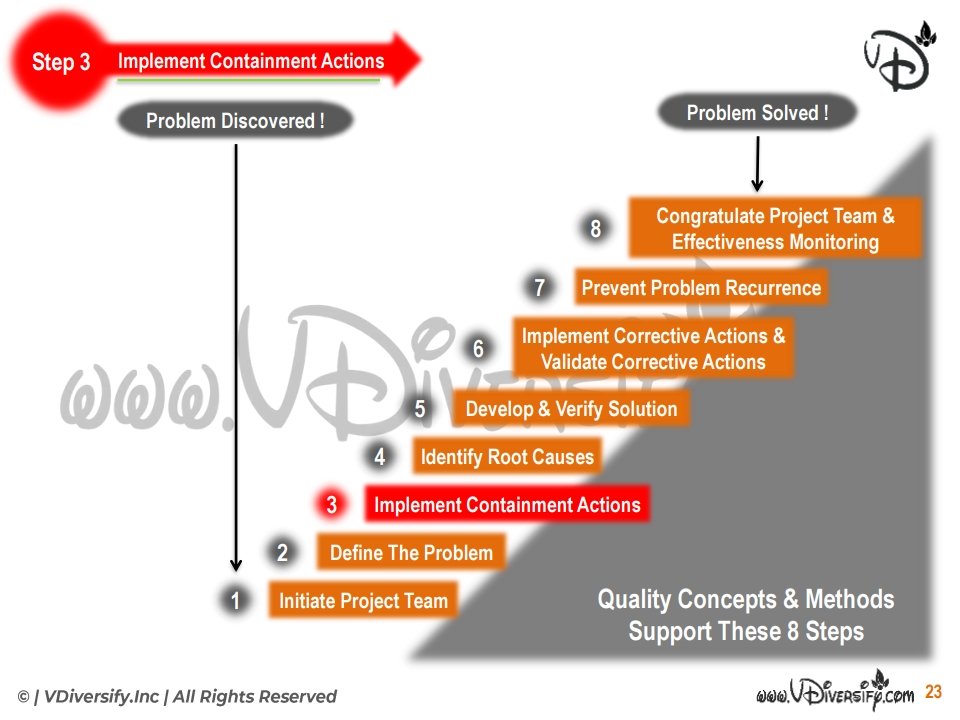

- 13.3 Step 3: Implement Containment Actions

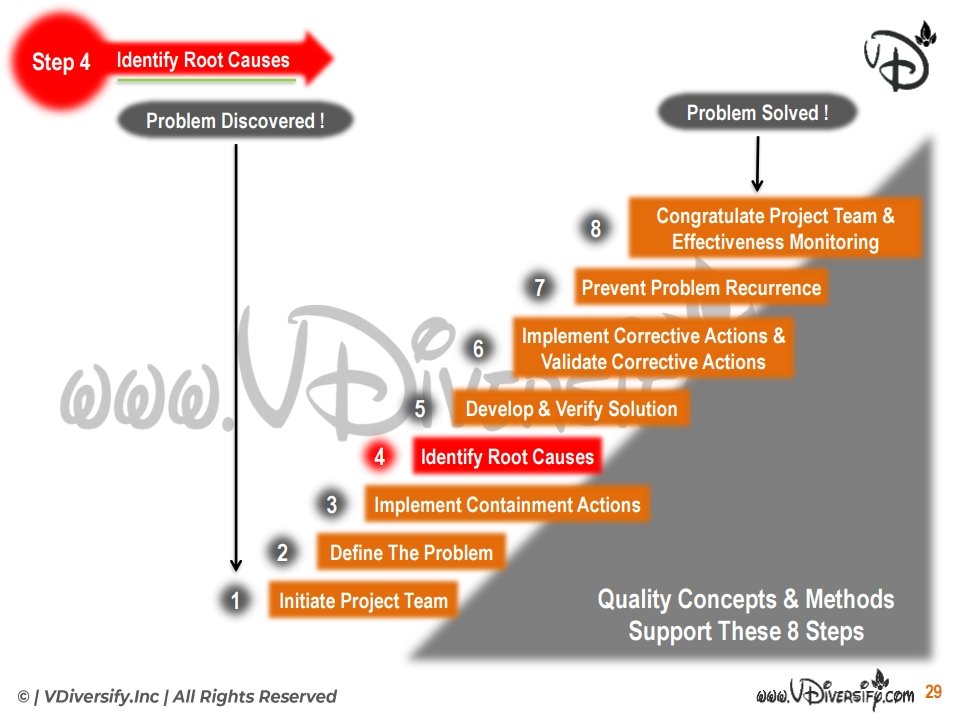

- 13.4 Step 4: Identify Root Causes

- 13.5 Step 5: Develop & Verify Solution

- 13.6 Step 6: Implement Corrective Actions & Validate Corrective Actions:

- 13.7 Step 7: Prevent Problem Recurrence

- 13.8 Step 8: Congratulate Project Team & Effectiveness Monitoring

- 14 Conclusion

- 15 8D Training Material For Free

8D Training Material

Solving Problems Now Made Easy – An Approach in an Automobile Industry To Solve Problems Effectively

Introduction To 8D Disciplines

Introduction to 8D Problem Solving Pdf and Definition of 8D Disciplines:

The 8D (Eight Disciplines) approach is a robust and systematic problem-solving process or methodology, that is widely adopted in the manufacturing, process and other industries.

It was first developed and popularized by Ford Motor Company, the 8D methodology has proven to be highly effective in product and process improvement.

It was being used by engineers and professionals to solve problems. The same legacy is being continued till date and is proven as the most effective problem solving tool across the world.

The main purpose of 8D is to identify, correct and eliminate risks of recurring problems. It involves its depth in more focus on product, process and system improvements thus by nullifying problems with root cause analysis and effective corrective action implementation.

Although it involves 8 steps (8D’s) it was later ambiguated by an addition of 2 steps, 0D called initial planning phase, 9D called horizontal deployment and 10D called effectiveness monitoring. It follows the logic of PDCA Cycle (Deming’s Cycle).

This 8D training material pdf is completely free and can be used by any organization, professionals, engineers, trainers or teachers all over the world for teaching its employees or students. This is the most effective best 8d problem solving training that you will ever find over the internet.

This training material is highly detailed and is backed by freely downloadable training presentation in power point (PPT) form or PDF form.

Recommended Article: A3 Report Problem Solving Tool

Recommended Article: 5 Why Analysis Tool

8D Training Material For Free

In this 8d training or This 8D training presentation or 8D training material pdf is highly detailed and is backed by freely downloadable training presentation in power point (PPT) form or PDF form (8d problem solving pdf). You can use this 8d presentation for presentation purposes at school, college, or in companies too.

Note: 8d problem solving tool: Please read the full Article to understand the principles of 8D Analysis pdf (8d analysis ppt/ 8d report pdf). After reading the full Article, you can able to download the 8d problem solving pdf.

<< 8D problem-solving training ppt / 8d problem solving process pdf >>

8D Training PPT Free Download

8d ppt free download / 8d problem solving ppt pdf:

If you are looking for 8d training material ppt free download, then you are in the right place. Not only that in this article we have clearly explained what is 8 d analysis and how to implement 8d. We have thoroughly explained all the 8d steps which you can read. If you don’t have time to read, then you can download the 8d pdf version from this article only. We have provided a download link at the bottom from where you can download the 8d training ppt.

Objectives of Web-based 8D Training

1. Background of History of 8D

2. Understand the Problem Solving Inhibitors and Definition of 8D (Eight-Disciplines)

3. Understanding Application, Differences between 8D & Continuous Improvements and Advantages of 8D

4. Understanding the Key Concepts and Principles of 8D Problem Solving

5. Understand the dynamics of Team-based Problem Solving

6. Understanding of Types and Tools of Root Cause Analysis

7. Understanding the Objective of each Step of the 8D Process

8. Understanding of Basics of PDCA Cycle

9. Define the Critical Success Factors for effective 8D Problem Solving

Problem Solving Inhibitors

1. Problem Described Incorrectly: Problem description was not clear enough or thorough enough to focus the team on solving the correct issue

2. Problem-Solving Effort Rushed: To move quickly, steps in the problem-solving process are skipped

3. Poor Team Participation: Team members do not participate effectively, so team failed to consider all the causes (lack of cross-functional expertise)

4. No Logical Process: A disciplined system to prioritize, analyze, and review data / information was not used

5. Lack of Technical Skills: Statistical and problem-solving methods are not known by team members

6. Management Impatience: Due to lack of knowledge of the problem-solving process, management demands to know exactly when a problem will be solved. This pressure causes the team to make an inadequate analysis

7. Misidentified Root Cause: A potential cause is quickly identified as a root cause, concluding the problem investigation. However, the problem returns since the true root cause was not eliminated

8. Permanent Corrective Actions Not Implemented: Although a root cause may be identified, action is taken to fully implement the permanent corrective actions. These actions often require management to approve costs and implement

Types of Problem Solving

1. Reactive (8D, 10 Steps): Activities undertaken to respond to a specific customer complaint (e.g.: product return) where a corrective action response is requested

2. Pro-Active (A3 Report): Activities undertaken to address performance gaps identified by data analysis (e.g.: key metrics)

3. Day-To-Day (“Quick Kills”):

· PDCA: Although “Just Do It” activities (e.g.: equipment breakdown)

· No team required

What Is Meant By 8D?

It is short for “Eight Disciplines,” which are 8 distinct steps of a systematic process for solving problems.

0D: Plan – Preparing for the 8D process

1D: Initiate Project Team

2D: Define the Problem

3D: Implement Containment Actions

4D: Identify Root Causes

5D: Develop and Verify Solution

6D: Implement Corrective Actions and Validate Corrective Actions

7D: Prevent Problem Recurrence

8D: Congratulate Project Team and Effectiveness Monitoring

Where Does It Come From?

There are several problem-solving approaches available, such as Kepner-Tregoe, the Deming Cycle, A3 and PDCA, etc. Ford Motor Company combined many of the successful elements from these into their Team Oriented Problem Solving (TOPS) Workshop, which this approach is based on.

Hint: Corrective action reporting from many diverse customers requires applying the 8D approach.

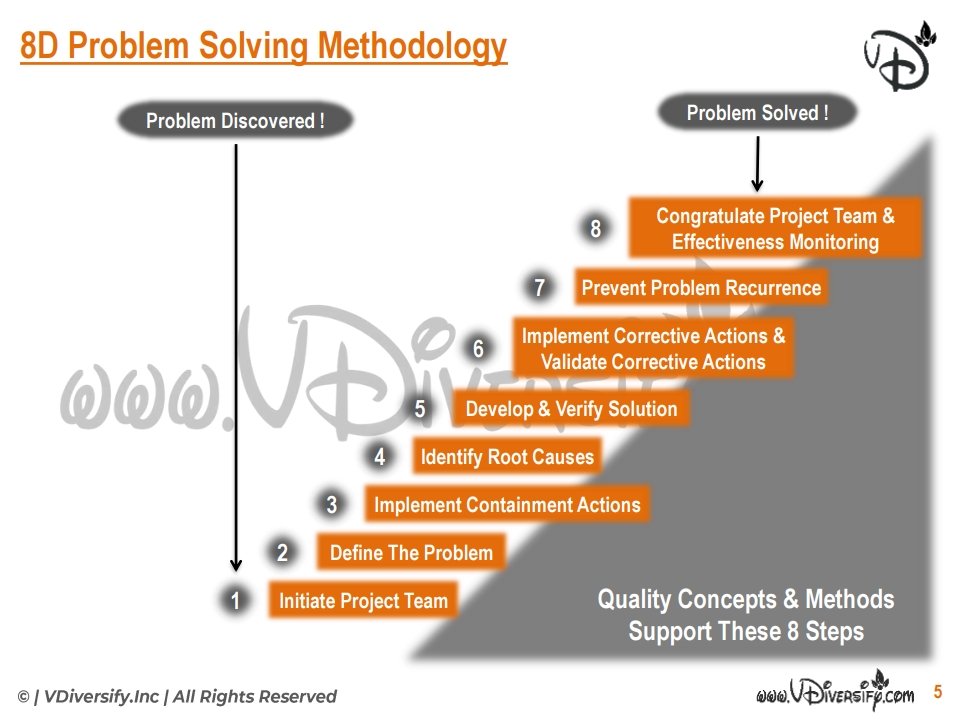

8D/8 Steps of Problem Solving Methodology?

8 steps of decision making process with examples ppt:

– 8 steps of problem-solving process

Applying 8D Methodology?

1. Predicated on Team Approach

2. Use for a Cause – Unknown Situation (all Significant Problems, Not just Customer Returns)

3. Fact-based, Data-Driven Decision Making. “If You Can’t Prove It, Don’t Say It !”

4. Eliminate the Problem, Not the Symptom

5. Requires Action Planning and Documentation for each Step of the Process

6. Focus On effectively using the Process, NOT on writing the report

Keep an Open Mind Facts / Data will guide us

8D vs Continuous Improvement?

8D Process/Approach | Continuous Improvement |

· Use an 8D Process where there is a Deviation between Actual Performance and Expected Performance · 8D is a Reactive Process | · Use a Continuous Improvement Process where the Actual Performance meets the Expected Performance, but a Higher Level of Performance is desired · Continuous Improvement is a Proactive Process |

Step 1: Form A Team | Use A Team Approach |

Step 2: Describe the Problem | 1. Initiate Project Improvement 2. Identify Customer Needs |

Step 3: Implement Containment Actions | |

Step 4: Identify Root Cause Actions | 3. Understand Current Process 4. Characterize Process with Data |

Step 5: Develop & Verify Solution | 5. Design New Process 6. Pilot & Verify New Process |

Step 6: Implement & Validate Corrective Actions | 7. Standardize New System |

Step 7: Prevent Problem Recurrence |

|

Step 8: Congratulate the Team | 8. Recognize Team |

Hint: The use of six sigma methods involves continuous improvement and innovation via specific tools used to: Define, Measure, Analyze, Improve and Control (DMAIC)

Advantages of 8D Methodology

8D Disciplines | 8D Steps [2022]

It is short for “Eight Disciplines,” which are 8 distinct steps of a systematic process for solving problems.

The 8D (Eight Disciplines) approach is a robust and systematic problem-solving process or methodology, that is widely adopted in the manufacturing, process and other industries.

Let’s get started with the 8D Problem Solving Training.

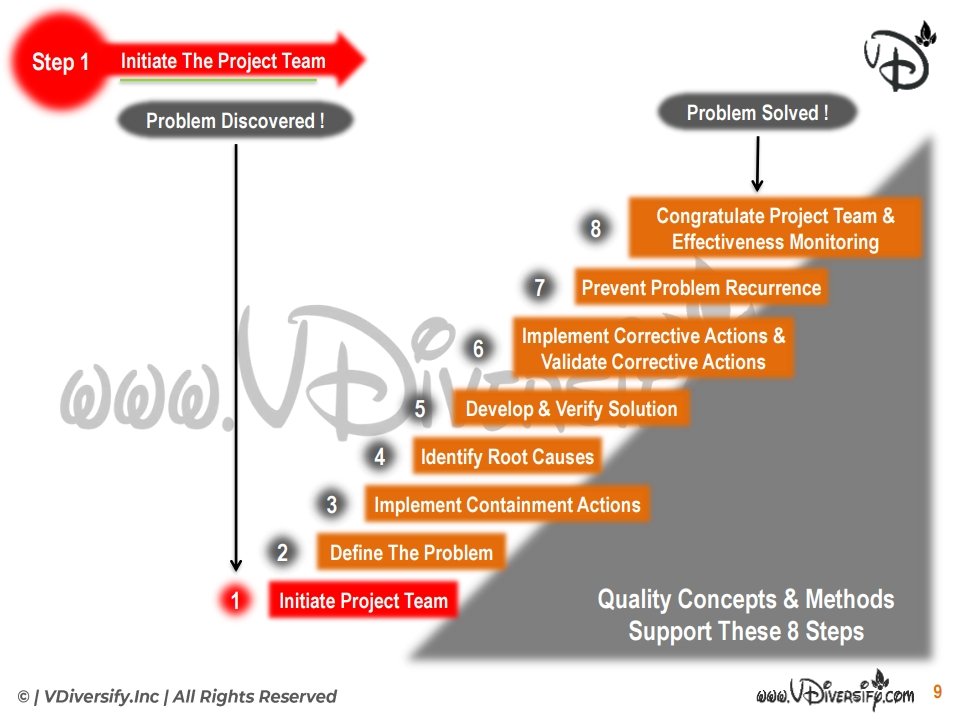

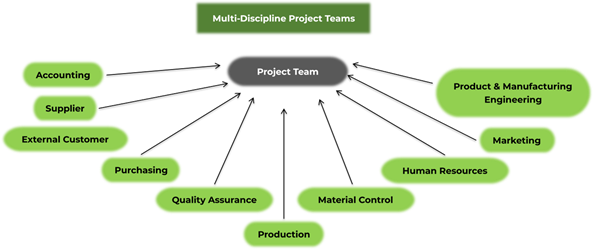

Step 1: Initiate The Project Team

– Step 1: Initiate The Project Team

Objective:

Establish a team of people with product and process knowledge, skill in the various technical disciplines or subject matter expertise (SME’s), and allocate time and authority to implement the actions to solve a problem

Supporting Concepts & Methods:

· Employee involvement / Participative

· Team Leadership Skills

· Meeting Facilitation Skills

Team Composition:

Good team members are personnel’s who are:

1. Willing to Contribute

2. Capable of Diagnosing Problems

3. Trainable in the Use of Improvement Methods

4. Team Players, rather than Individual Participants

Team Size:

3 to 7 members is optimum. With fewer than 3 members, creativity and skills are limited and with more than 7 the team is too large for effective team dynamics

Hint: Experts with specific skills can be rotated in and out of the team as their skills are needed

Team Formation:

– Team Formation for 8D Analysis

1. Identify the expected time commitment from team members and ensure availability

· Management support needed

2. Goals must be clearly specified, quantifiable, and supported by all

Why A Team Approach?:

Doing business today is tougher than ever, especially when you don’t have any business idea with you:

· More demands

· Complex problems

· Need to avoid wasted money, time and effort

Hint: A team of individuals can combine their skills / knowledge to solve these problems that are beyond the capability of any one person to solve alone

Advantages of Teams:

1. Skills

· More Talent

· More Experience

· More Knowledge

· More Technical Competence

2. Communication

· Cross Departmental Lines

· Increased Productivity (More Theories & Ideas)

· Increased Dignity & Morale

3. Participation

· Consensus Decision-Making

· Buy-in To Changes

· Job Enrichment

4. Effectiveness

· Better Solutions

· Solutions More Likely To Be Accepted

· Responsibility To Complete Slated Mission

Pitfalls To Avoid:

· No leader empowered to implement ideas

· No champion assigned or available to assist the team in time of need

· Personality conflicts, domination by one member, or negative attitudes (why am I here?)

· Excessive management expectations, not enough time

· Insufficient problem-solving skills by members

· Undefined progress – No sense of urgency, No goals

· Lack of data / facts, not shared by all

Hint: “If you don’t know where you’re going, any road will get you there”

Hint: “If there’s a doubt, then there is no doubt…Get the FACTS!!”

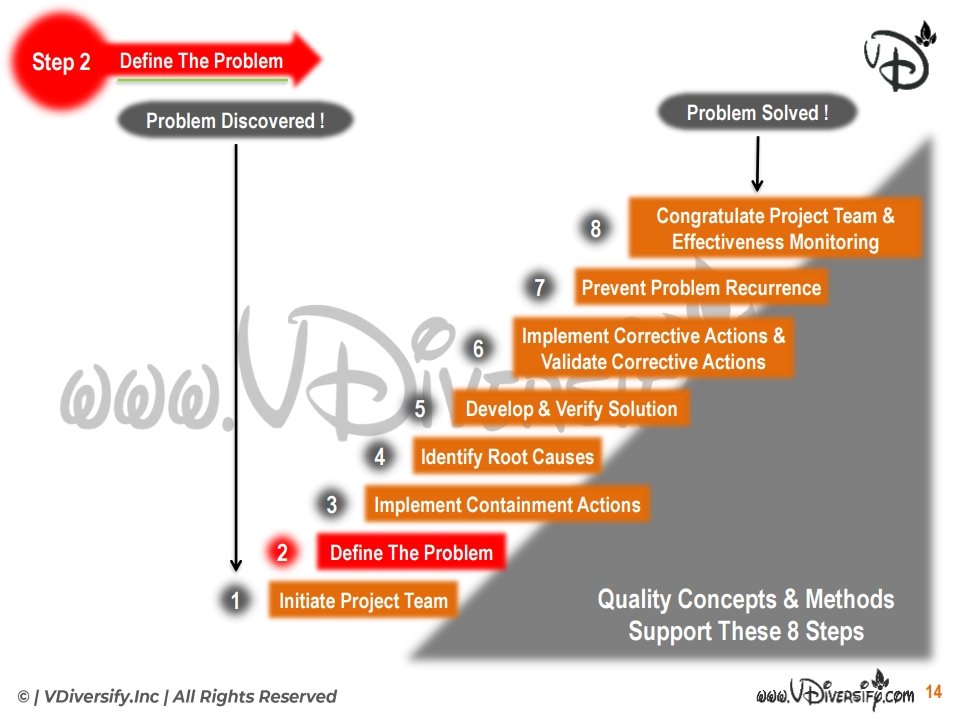

Step 2: Define The Problem

– Step 2: Define The Problem

Objective:

To define the extent of the problem and its effects in quantifiable terms, resulting in a narrower focus for containment and root cause-finding efforts

Supporting Concepts:

1. 5W2H

2. Pareto Diagrams

3. Control Charts

4. Is / Is Not Analysis

5. Check Sheets

Define The Problem:

Hint: “A problem well stated is a problem half-solved”

1. Rarely will a problem description be complete/final at the beginning of the 8D process

2. Problem cannot be completely described until it is well understood

· Problem description should be revised and updated to incorporate new facts / data

3. Quantify the gap between what “is” and what “should be”

Supporting Tools:

1. Customer Complaints

2. 5W2H

3. Data Collection

· Flow Diagram

· Collect Data (Attribute & Variable)

· Stratify (Checksheets & Pareto’s)

· Statistical Data (SPC & Cpk, etc.)

4. Comparative Analysis

· Is / Is Not

· Table of Facts

5. Formulate Problem Statement

· Include Benchmark

· Incorporate All Important Facts

· Concise & Precise

1. Customer Complaints:

· Describe the symptoms experienced by the customer (i.e., user) in their terms

· Ensure the complaint is clearly and fully understood

a) Direct customer contact (ask clarifying questions)

b) Customer representatives may be on the team

c) Understand the problem from the customer’s viewpoint

2. 5W2H:

Characterize the problem for further analysis through 5W2H:

Who? – Identify Who is associated with the problem. Which customer(s) are complaining? Which internal group(s) are complaining?

What? – Describe the problem adequately. What is the defect and gap from “Target”? What part or object is involved? Does the severity of the problem vary?

Where? – If the defect occurs on a part, where is the defect located? Use a location check sheet / OPL. Where was the defect found (geographically)? What is the geographic distribution of complaints?

When? – Identify the time when the problem started and past history (trends). Do all production shifts experience the same frequencies? What time of the year does the problem occur? When did the non-conformance occur? What was the operating time? What shift? What season?

Why? – Define why this is a problem for the customer or organization. Translates “How Big” (see next slide) into total business impact

How? – In what mode of operation was the problem discovered? What procedures were being used? What environmental conditions were present?

How Big? – Quantify the extent and severity of the problem (Quantity, Percent, Cost, DPPM, etc.)

3. Is / Is Not Tool:

· Search: Search for a comparative basis (act like a detective, include similar parts / situations).

· Put boundaries around the problem to narrow the search for a root cause. Ask numerous questions and gather as much data as possible to establish the “Facts” of the problem

a) Who is experiencing the problem?

b) Where was the discrepancy observed?

c) Where on the part is the defect?

d) When was the issue observed?

e) How many bad parts are in the system?

f) Who could be experiencing the problem but is not?

g) Where could the issue have been observed but was not?

h) Where on the part could the defect be but is not?

i) When could the issue have been observed but was not?

j) How many bad parts could be in the system but are not?

· Know The Facts: Make a table of the facts discovered in the search

Sl No. | Is | Is Not | Get Info On |

1 | What is the object with the defect? | What could be, but Is Not, the object with the defect? |

|

2 | What is the defect? | What could be, but Is Not, the defect? |

|

3 | Where is the object with the defect observed? | Where could the object with the defect be observed, but Is Not? |

|

4 | Where is the defect on the object? | Where could the defect be on the object, but Is Not? |

|

5 | When was the object with the defect first observed? | When could the object with the defect first have been observed, but was Not? |

|

6 | When was the object with the defect been observed since then? | When could the object with the defect have been observed since then, but was Not? |

|

7 | When is the defect first observed in the cycle of the object? | When could the defect first be observed in the cycle of the object, but Is Not? |

|

8 | How many units of the object have the defect? | How many units of the object could have the defect, but do Not? |

|

9 | How much of each unit is affected? | How much of each unit could be affected, but Is Not? |

|

10 | How many defects are on each unit? | How many defects could be on each unit, but are Not? |

|

11 | What is the trend? | What could be, but Is Not, the trend? |

|

Identify Differences:

Ask questions to understand what is the difference between the “Is” and “Is Not” conditions:

· Helps to focus the thoughts towards the specific problem area

· Avoids trying to “boil the ocean” by making problem scope more manageable

· Important, but often overlooked step in process

4. Ask, “What Changed?”

Problems appear because something has changed. The search for the root cause is a search for changes

Ask, “What Changes have occurred?”

· What changes have occurred in the plant?

· What new suppliers are being used?

· Have any new operators been hired?

· Has new material been used? A new batch?

· Is the process capability the same as usual?

· Was the weather or environment or surroundings unusual when the problem occurred?

Hint: No Changes, No Problems

5. Develop Problem Statement:

The problem statement is the expression of the difference between what should have happened and what actually happened.

· Includes the baseline or benchmark for good performance

· Contains reference to one problem only

· Each problem is unique and need to be clearly understood in order to be solved

· Should include information from all of the 5W2H sections

6. Common Pitfalls:

Common pitfalls when writing problem statements include:

· Problem statement is too general (lacks detail and specifics). A general problem is difficult to solve correctly

· Problem statement describes a root cause instead of problem effects

§ Don’t get into a root cause debate at Step 2

§ Step 4 is for determining the root cause

§ Step 2 is for clearly describing the problem to be solved and quantifying the effects on downstream users or customers

· Embedding a solution in the problem statement. When we embed a solution into the problem statement

§ Steps 5 and 6 are for solutions (corrective actions)

§ Don’t get locked into a decision before all facts are known

Hint:

1. Problem Statement with Embedded Solution:

Revise order processing procedures to remedy recent delays in processing customer orders

2. Revised Problem Statement: Frequent delays and errors in processing orders for all customers during the last 2 months

3. How could this statement be improved further?

Step 3: Implement Containment Actions

– Step 3: Implement Containment Actions

Objective:

To define, implement and verify the effectiveness of Temporary Actions to isolate customers from the effects of the problem.

Supporting Concepts & Methods:

1. Manufacturing Records

2. Histograms

3. Control Charts

Implement Containment Actions:

Containment Actions Are:

1. Intended to protect a customer from effects of a problem

2. A temporary fix to buy time for root cause analysis and C/A implementation (“stop the bleeding”)

3. Not cost effective (use good business sense and judgement when choosing)

4. Quick fixes designed only to address the effect of a problem (usually detection-based)

5. Must remain in-place until permanent C/A implemented

6. Must include a review of product at all phases (see details below)

· Step applies to all quality issues, not just product returns

Material / Product Locations (Containment):

1. Raw Material

2. Semi-finished Goods (WIP)

3. Finished Goods

4. At Customer

5. At Supplier

6. In Transit (from Supplier or to Customer)

7. Shipping and / or Receiving Dock

8. In Transit (from Supplier or to Customer)

9. Materials on Order (Future Shipments from Supplier)

Hint: Danger – Do not consider containment action a permanent solution to a problem.

Common Containment Actions:

1. 100% inspection to sort out defects

2. Stop production from a known source of the problem

3. Purchase parts rather than make in-house

4. Single source to one rather than multiple suppliers

5. Use back-up tooling (fewer cavities/nests)

6. Others?

Containment Follow-up:

After implementing containment actions, verify their effectiveness by measuring effects in quantifiable terms:

· The effectiveness of the containment action must be monitored to ensure proper protection of the customer is maintained

· The benefit of a containment action must last until the root cause is identified and permanent corrective action is implemented

· Decision making tools are used in this step to ensure proper thought is given when choosing the actions

· Risk assessment is an important step during the decision-making process

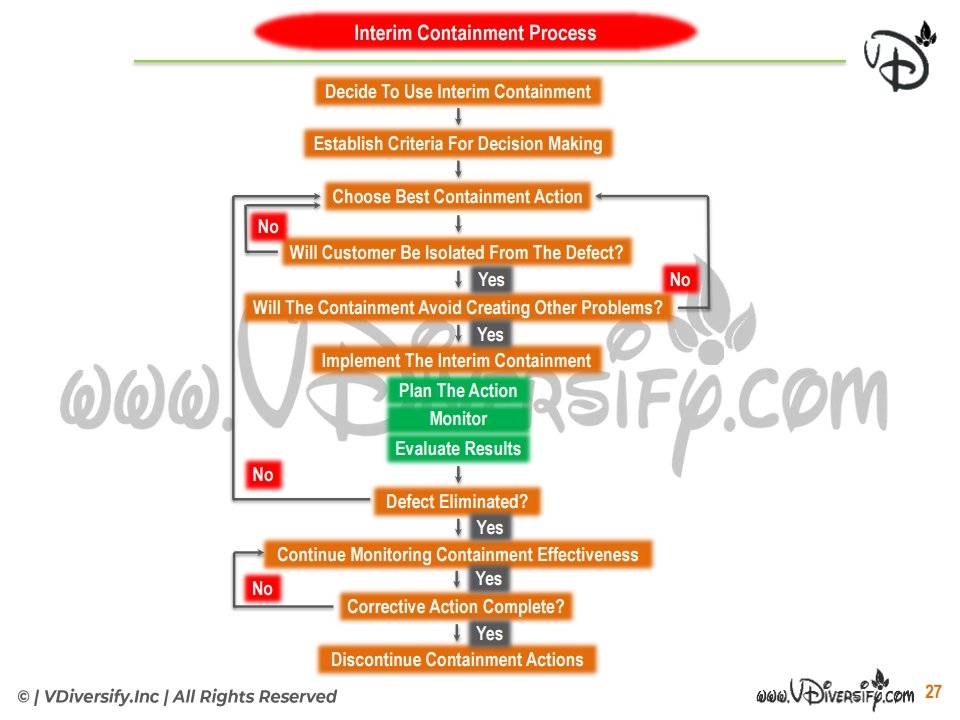

Interim Containment Process:

– Interim Containment Process

Buy Time:

Interim containment is a legitimate method to buy time.

Containment actions compared to the band approach:

Interim Containment | Characteristic | Band Aid Approach |

X | Attack Symptoms | X |

X | Added Costs | X |

X | Monitored During Use |

|

X | Documented |

|

X | Effectiveness Verified |

|

X | Replaced By Effective CAR |

|

Hint: Caution!

Interim containment liabilities:

1. May be forgotten and remain in effect

2. Costly due to sort / re-work

3. Not necessarily 100% effective

4. Risks must be assessed (customer, plant, etc.)

Step 4: Identify Root Causes

– Step 4: Identify Root Causes

Objective:

To identify and test potential causes using the problem description and test data to isolate and verify the root cause.

Supporting Concepts & Methods:

1. Brainstorming

2. C/E Diagrams

3. 3L5W (3-Leg 5 Why)

4. Histograms

5. Control Charts

6. Capability Studies

7. Gauge R&R

8. Scatter Diagrams

9. Design of Experiments

10. FMEA’s

Types of Root Cause:

There are 2 types of root cause:

1. “Occurrence Root Cause”

· A breakdown in prevention activities (e.g.: training, drawings and fixtures, etc.)

· The specific local cause that resulted in the specific problem reported

2. “Escape Root Cause”

· A breakdown in an inspection / detection operation

· Explains why the defect / problem was allowed to “Escape” to a downstream operation (e.g.: Next manufacturing step or customer)

Both Types of Root Causes must be addressed:

· Only addressing “Occurrence” allows similar causes to continue to escape to the customer (appears to be a repeat occurrence)

· Only addressing “Escape” leaves unnecessary wastes (e.g.: scrap / re-work) in the system

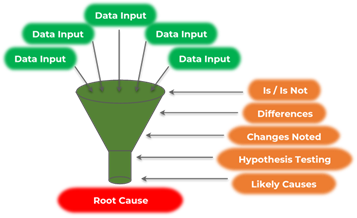

The Fact Funnel:

– The Fact Funnel Diagram for Root Cause Analysis

Brainstorm Potential Causes:

A good way to produce a maximum number of ideas is to conduct a brainstorming session:

· Cause-and-Effect Diagram (C/E Diagram) is an excellent tool to assist in brainstorming for causes

· All possible causes of the problem should be identified

· The more detailed the C/E Diagram, the greater chance the root cause will be included

Hint: All likely, potential, and even improbable causes discussed in the meeting should appear on the Fishbone (Cause and Effect) Diagram

Cause And Effect Diagram:

Possible Causes For Non-Conformance Possible Causes For Non-Detection

Ask 5 Why’s?:

Review symptoms – or effect – of the problem. To drive your team’s understanding from the effect to the causes, Ask, “Why?” Five times. Ensure that at-least a minimum of 3 Why’s are Asked without fail.

Example:

Problem: Machine stoppage

Typical One Why Exchange: “Why did the machine stop?”

Root Cause: “Fuse blew due to an overload”

Corrective Action: Replace the fuse: End of problem?

5 Why Exchange (Example of Why-Why Analysis):

Problem: Machine stoppage

Recommended Article: Examples of 5 Whys

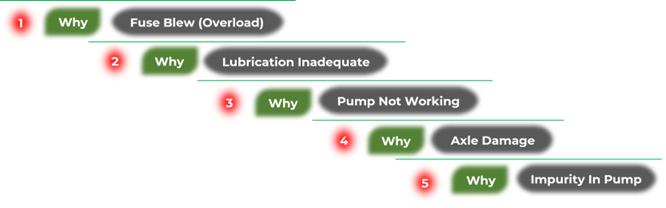

Why-Why Analysis:

Why 1: Fuse blew (overload)

Why 2: Lubrication inadequate

Why 3: Pump not working

Why 4: Axle damage

Why 5: Impurity in pump

Corrective Action: Install a filter on the lubricator pump

Hint: Ask “Why?” until the answer is not known or can’t be controlled, then proceed with the investigation

This tool allows the user to reduce the likelihood of solving effects, rather than the base problem itself.

· Is this a good permanent solution to the problem?

· Could we have asked “Why?” Once more?

· Does a filter on the lubrication pump act as a permanent solution?

Hint:

1. What must you do with a filter? (clean / replace)

2. How did the impurity get into the fluid or pump?

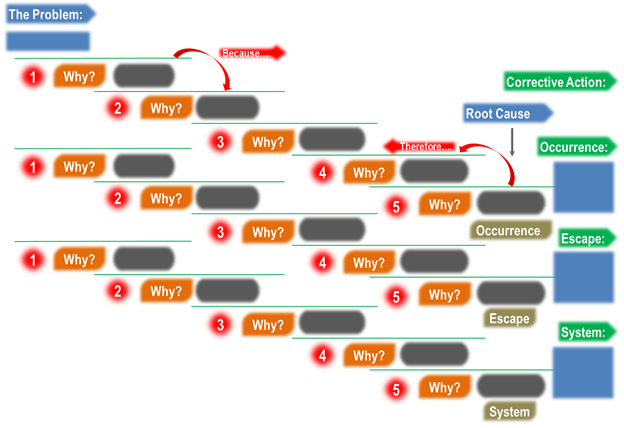

3-Leg 5-Why Analysis Work Sheet (3-legged Why-Why Analysis):

Enhances basic 5-Why analysis tool. Use all (3) paths to thoroughly investigate why the specific non-conformance occurred, why it was not detected by process controls, as well as, why the overall governing system, policies, procedures, or process allowed this non-conformance (and perhaps others like it) to occur. Check continuity of logic by reading back using the “Therefore” test.

– 3-Leg 5-Why Analysis Work Sheet

Verification Criteria:

The underlying root cause has been reached only when the final why satisfies these criteria:

· It initiates and causes the event we are seeking to explain

· It is directly controllable

· The elimination of that root cause will result in the elimination or reduction of the Problem

Select Root Cause:

1. Interpret data and develop potential hypothesis:

· Many different ideas may exist as to what the true cause of a problem is

2. Compare all hypothesis to Is / Is Not data (investigation facts):

· The true cause will have all facts either supporting the explanation of being unrelated

· Any fact refuting a hypothesis means that either the fact is incorrect (bad data) or the hypothesis needs revision

3. Continue Research as needed:

· Verify / Validate Facts in Question

· Revise hypothesis or identify Cause interactions

Hint: Always applies to “Occurrence” root cause, but can also apply to “Escape” root cause

Be Willing To Re-Evaluate:

Many have the mistaken belief that data-oriented problem solving consists of collecting relevant data, Analyzing the results, and determining the correct solution. After data is collected, new questions arise, and original assumptions may change. More than one iteration is usually necessary to find the root cause. The path is not a straight line, but rather a spiraling one.

Verification:

Hint: Turn It On …… Turn It Off …….

Through experimentation (or simulation), verify that the real root cause has been found. It should be possible to create and eliminate the problem by installing and removing the cause.

Hint: The true root cause should be able to explain all of the data and facts collected up to this time.

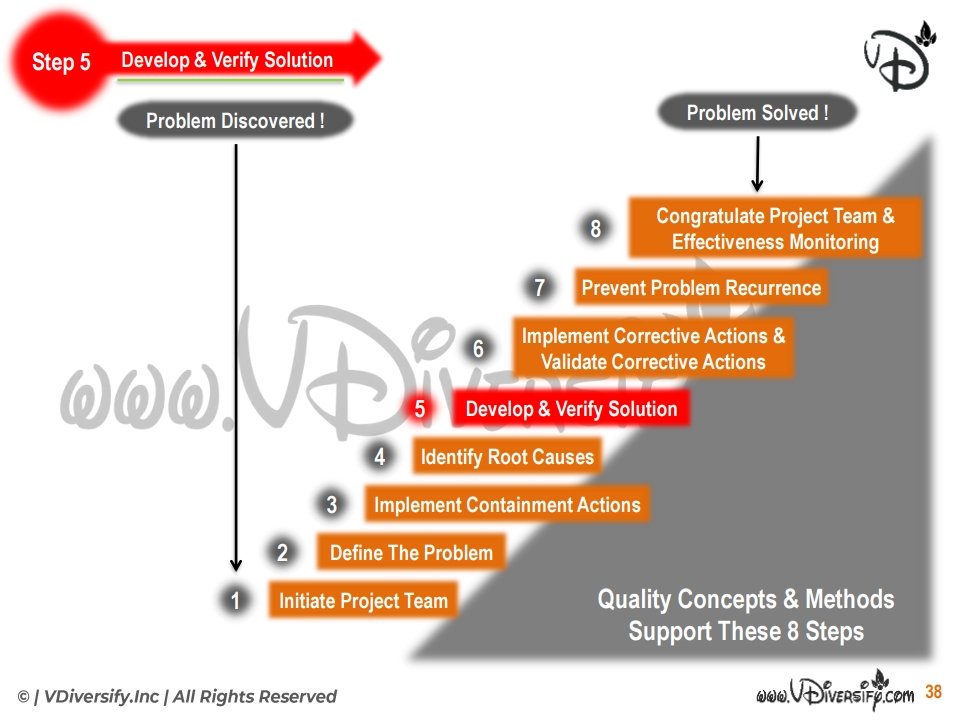

Step 5: Develop & Verify Solution

– Step 5: Develop & Verify Solution

Objective:

To select from alternative solutions to the problem and verify that the problem causes are eliminated, without introducing new problems

Supporting Concepts & Methods:

1. Brainstorming

2. Risk Assessment

3. Capability Studies

4. Decision Matrix

5. Gauge R&R

6. Control Charts

Choose Verify Corrective Actions:

· Corrective action decision criteria are established through the decision-making process

· Objectively evaluate each possible action against a predetermined decision criterion

· Prove that the corrective action (or combination of actions) will eliminate the problem

1. Conduct verification tests

2. Remove containment temporarily

· Only normal production influences should be present

· Establish indicators to ensure the defect is eliminated with high confidence

Verify The Solution:

It is critical to verify that the solution will eliminate the problem.

· Review should happen before implementation of the corrective action

1. Prove that the Fix will work as Planned

2. No unintended Negative Consequences

Verification Approaches:

1. Design Verification Testing

2. Production Validation Testing

3. Bench / Lab Testing

4. Simulation

Decision Making Results:

1. Describe the end results

· What is the overall objective that must be achieved?

2. List the decision criteria

· Differentiate between “Needs” and “Wants”

· Pros and Cons must be measurable and realistic

· Make sure you cover all the bases and your criteria represent all areas (Time, Money, Law, People, Production, etc.)

3. Identify the potential solutions

· Identify all the choices you have that may work

· Make certain all Ideas are included

· Balance reactive (inspection-based) and preventive (error-proofing) activities

4. Evaluate the potential solutions

· Rank options against identified criteria

· Identify any potential risks of each solution

· Assess the probability of the risk occurring and the seriousness to your decision if it did occur

5. Choose a solution or set of solutions

· Use results of assessment (prior step)

· See next slide for decision making worksheet

· A robust Solution must consider:

1. Cost

2. Timing

3. Effectiveness

4. Implementation Issues

5. Potential Side Effects

Hint: Select the option which provides the results you want to create and has acceptable risk connected with it.

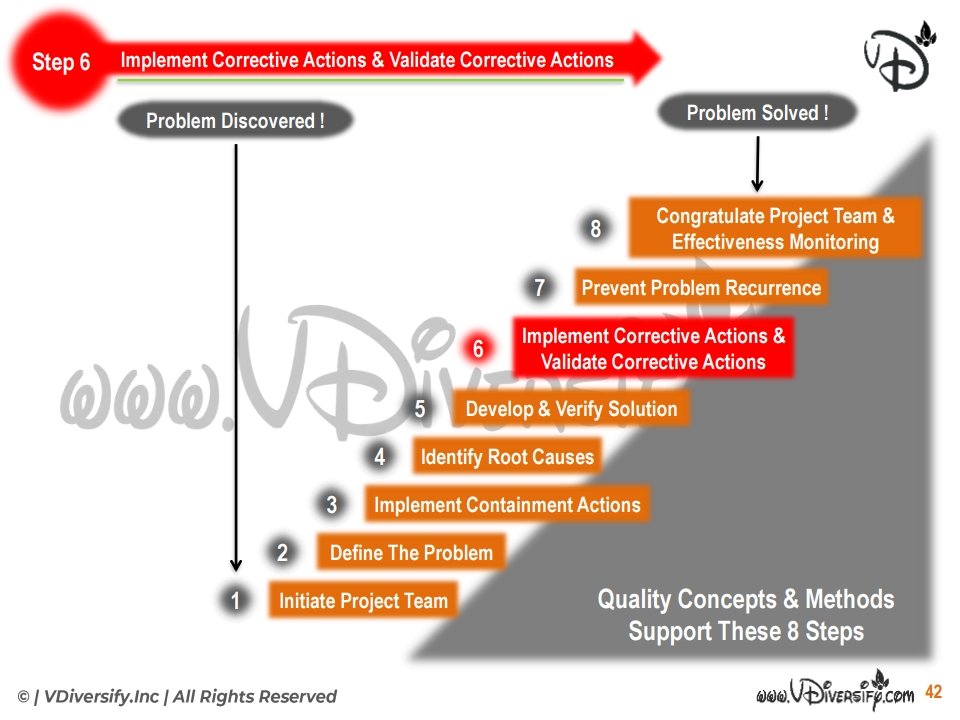

– Step 6: Implement Corrective Actions & Validate Corrective Actions

Objective:

Develop implementation action plan:

· Define actions, responsibilities, timing, and required support

· Define prevention and protection actions. Involves both action planning and immediate validation of actions

Supporting Concepts & Methods:

1. PDCA Process

2. Process Flow Charts

3. Control Charts

4. Standard Work

5. Capability Studies

6. Control Plans

7. FMEA’s

8. Error Proofing

PDCA Cycle:

PDCA cycle also called by the name Deming’s cycle, stands for Plan, Do, Check and Act.

Plan:

Develop plan for implementing specific actions:

1. What documentation needs to be updated?

· Work instructions, drawings, control plans, FMEA’s, computer programs, and etc.

2. What people need to be retrained?

· Operators, inspectors, engineers, other support personnel, and etc.

3. What organizations need to be notified?

· Internal departments, suppliers, customers, and etc.

4. What new problems are presented by changes and how will they be addressed?

· FMEA, risk assessment, and etc.

5. Who owns each task and what is the targeted implementation date?

6. How will progress be tracked?

7. Develop contingency plans if problems are encountered

8. When will containment actions be removed?

Do:

Execute the plan

1. Use existing control processes

· Document control

· Engineering change (ECO / ECR)

· Customer notification or process change (PCN)

· Supply chain processes

· Training processes

2. Identify the effective date of changes

· Operators, inspectors, engineers, other support personnel, and etc.

Program Management Tools:

· Gantt Charts (High Level)

· Task Lists (Detail Level)

· Report Outs

Hint: Even a great plan can fail, if not executed properly

Check:

Review process to ensure things are working according to plan

· Track progress and determine resources needed to meet commitment dates

· Review performance results to ensure improvements are being realized

· Review costs to ensure financial impacts are in-line with expectations

· Ensure that no unintended consequences are happening (Quality, Efficiency, Safety, and etc.)

Act:

Make necessary adjustments as needed

· Reapply containment actions if problems still present and revise corrective actions (back to problem solving and “Plan” phase)

· Deploy resources in different way to get execution back on track

· Move on to next opportunity if everything is complete and achieving desired results

Remember:

Corrective actions remove the root cause of the problem, not just the effect. corrective actions are Permanent. The problem should not be able to return.

Step 7: Prevent Problem Recurrence

– Step 7: Prevent Problem Recurrence

Objective:

To modify the methods, equipment, materials, process procedures and management systems and practices to prevent related problems from occurring (same or similar issues).

Supporting Concepts & Methods:

1. Process Flow Charts

2. Standard Work

3. Error Proofing

4. FMEA’s

5. Control Plans

Types of Preventive Actions:

1. Sustain the gains for current improvements

· Update procedures / documentation, training, fixtures, error-proofing, and etc.

2. Similar problems within the same work area

· Apply improvements to prevent similar problems from occurring

· Use FMEA to help identify opportunities (e.g.: Multiple causes for a single failure mode / symptom)

3. Same or similar problem in another part of the organization

· Apply improvements to prevent future problems

· Learn from prior mistakes / problems

· Share the learning

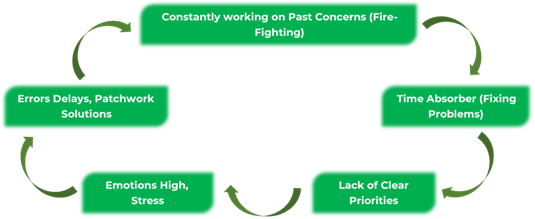

Lack of Prevention Leads To A Cycle of Waste:

– Step 8: Congratulate Project Team & Effectiveness Monitoring

Objective:

To recognize all the team members for their individual and collective efforts and develop a climate for on-going improvements.

Supporting Concepts & Methods:

1. Employee involvement / participative management

2. Interpersonal communication skills

Recognize The Team:

If recognition is not given, team members are less willing to participate and are likely to become Discouraged. Recognition and feedback is the most effective method available to shape behavior.

Hint: “You Get What You Expect”

1. Be specific on facts of each individual’s input

2. Sincerity in both public and private, recognition is required to make it acceptable to the recipient

Hint: If You Don’t Believe It, The Team Member Won’t Either

Congratulate The Team:

Recognize the team’s collective efforts (both past and present) in solving the problem and show appreciation for individual contributions.

Team members are in the best position to begin this process:

1. People respond favorably to sincere, thoughtful recognition

2. Recognition makes people “Feel Good” about themselves, their achievements, and the organization that took the time to acknowledge them

3. Recognition provides very positive reasons for team members to participate in future efforts

Forms of Recognition:

1. Top Management Letter

· Deliver at home (Family)

· Post on Bulletin Board (Co-Workers)

· Place in Personnel File (Management)

2. Performance Review

· Include as Major Contribution

3. Plaque

· For Outstanding Contribution

· Personal, and Specific to Problem Solved

Hint: Recognition needs can differ greatly from person to person.

Conclusion

Download 8D PPT / 8D Training PPT / 8D Training PDF:

This 8d analysis ppt is complete 8d training material that you can use to teach your colleagues and team members. This is the introduction to 8d problem solving pdf that you ever find on the internet, that to for free.

In this 8d problem solving training, the 8D (Eight Disciplines) approach is a robust and systematic problem-solving process or methodology, that is widely adopted in the manufacturing, process and other industries.

If you are looking for an 8D PPT (8D Methodology PPT), then you are in the right place. This 8d training material pdf is highly detailed and is backed by freely downloadable training presentation in power point (PPT) form or PDF form, which you can download from the below links for 8D training PPT or 8D training PDF.

After reading this 8D problem solving ppt pdf (8d report training ppt) from our website, you don’t have to go anywhere searching got 8D PPT, as this 8d problem solving ppt covers all the requirements of 8D.

This 8d problem solving training ppt (8d report ppt) is a very useful 8D training PPT on “8D Approach” for analysis of customer complaints or inhouse complaints. This 8D training PPT is going to be best 8d training material you are going to get over the internet.

Comment below if you need an example for 8d problem solving example ppt.

Why wait? Download problem solving ppt download here! (8d problem solving pdf / 8d report pdf):

8D Training Material For Free

In this 8d training or This 8D training presentation or 8D training material is highly detailed and is backed by freely downloadable training presentation in power point (PPT) form or PDF form (8d problem solving pdf).

Note: Please read the full Article to understand the principles of 8D Analysis (8d analysis ppt). After reading the full Article, you can able to download the 8d problem solving pdf.

Download 8d template ppt free or 8d report template ppt:

8D Problem Solving Example PPT / 8D Example

8d problem solving ppt free download:

Here is an example of 8d which you can refer and prepare your own 8d. We have given two 8d examples for your understanding. You can also download the same in the 8d example pdf format. This is a 8d problem solving case study ppt which you can download along with examples. In this article, there are 2 examples of 8d report example ppt.

“Hey, I am Sachin Ramdurg, the founder of VDiversify.com.

I am an Engineer and Passionate Blogger with a mindset of Entrepreneurship. I have been experienced in Blogging for more than 5+ years and following as a youtuber along with blogging, online business ideas, affiliate marketing, and make money online ideas since 2012.

8 thoughts on “8D Training Material PDF [2022] [PDF/PPT] | 8 Disciplines of Problem Solving”